This portable aerosol test chamber gives you the ability to characterize and determine the field performance of your aerosol detection and collection systems in their intended operational environment. Air samples that include naturally occurring background can influence the results for biological detectors and collectors. Also, the challenge aerosols often used in field tests may be harmful, toxic or subject to regulatory environmental control. The Compact Aerosol Test System (CATS) gives you full control of your aerosol test environment in a real world setting.

Amtech’s CATS platform allows testing professionals to quickly and accurately determine the effectiveness of field deployed aerosol detectors/collectors. Its unique features allow challenge aerosols to be combined with air sampled from the ambient environment, while minimizing the risk of exposure to personnel or the environment.

Typical Applications For This Aerosol Test Chamber

- CBRN instrumentation testing

- Development of sampler, collector and detector technologies

- Regular validation of equipment performance

- Integrated bio-detection system validation (Vehicles and other platforms)

CATS Features

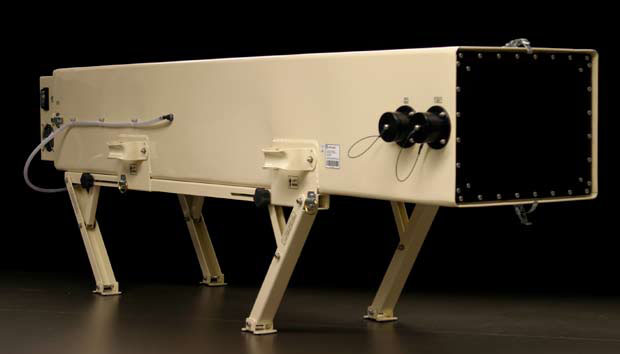

- Compact, portable platform…easily transported and assembled

- Ambient air inlet…allows ambient background into test section

- Simple setup and operation…achieves rapid test throughput

- HEPA filtered outlet…avoids exposure to environment/personnel

- Rugged construction…enables indoor or field use

- Convenient sampling ports…allows simultaneous testing of two devices

- Automated control software…enhances test repeatability & throughput

- Decontamination port…fast and effective vaporous decon.

Description

The CATS is a portable aerosol test chamber system consisting of an aerosol generation/dilution system (ADS) and an aerosol test duct (ATD). The CATS provides a means to disseminate and dilute a prescribed dose of the challenge aerosol, combine the test aerosol with unfiltered ambient air and deliver the aerosol cloud over the sample ports. Exposure of personnel or the environment to the aerosol is avoided by maintaining a negative pressure within the ATD and using HEPA filtered outlets.

Principle of Operation

The aerosol detector/collector is mounted beneath the ATD using an adapter plate (user customizable orifice size). The dissemination source is attached to the ATD, using the optional ADS diluter. A control module allows the concentration of the injected aerosol to be established. HEPA outlet filters prevent the aerosol from leaving the test section uncaptured. The ATD can be operated independently of an ADS with ambient background air only. The operator selects the test parameters using the included user interface and installs a referee system in order to validate the sampler/collector results. Upon executing the test protocol, the control software automatically performs the entire test. Finally, the operator removes the sample along with the reference sample and submits them for analysis. The CATS is immediately available for the next trial.

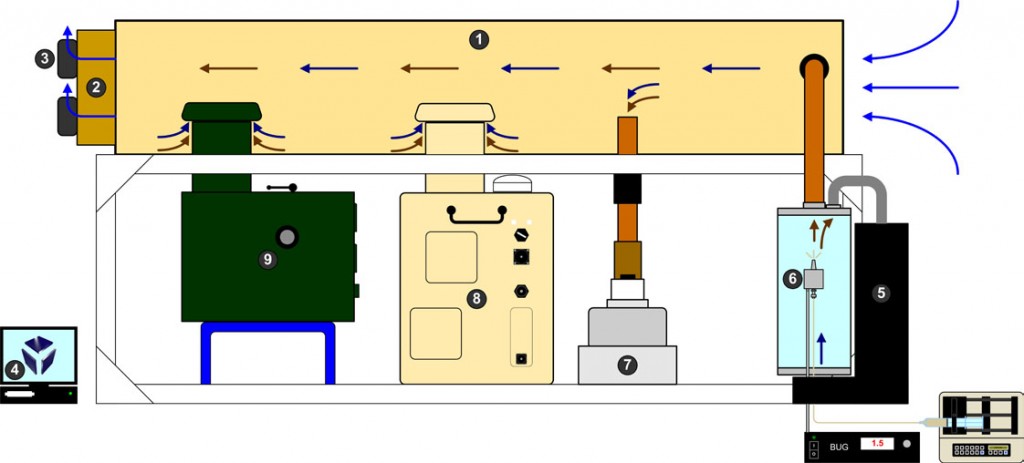

The diagram below displays the air flow path of the ambient air and aerosolized biological simulant through the CATS platform. Ambient air is drawn through the ATD (1) while the biological simulant is disseminated by nebulizer (6) through the ADS (5). The mixture of ambient air and biological simulant is drawn by the blowers (3) past the reference sampler (7), the detector (8) and the collector (9) before being exhausted through the HEPA filter (2). The ADS and the ATD are controlled remotely via a PC user interface (4).

Specifications

CATS – Compact Aerosol Test System

ATD (Aerosol Test Duct) and ADS-A20 (Aerosol Diluter)

| Dimensions (W x H x D) | ATD-002 (without stand): 210 x 62 x 38 cm (83 x 25 x 15 in) ADS-A20: 28 x 79 x 43 cm (11 x 31 x 17 in) |

| Weight | ATD-002 (without stand): 35 kg (77 lbs) ADS-A20: 14.9 kg (33 lbs) |

| Power Requirements | ATD-002 / ADS-A20: 100 – 240VAC, 2.8 A (max), 50/60Hz |

| Communications | 10/100baseT Ethernet (wired) |

| Included Software | LabVIEW executable, Web-based diagnostics interface |

| Minimum PC Requirements | MS Windows XP/Vista, Pentium III 800MHz or equivalent, 128MB RAM, Wired Ethernet port |

| Maximum Exhaust Flow | ATD-002: 1500 slpm ( 53 cfm) ADS-A20: 200 slpm (7.1 cfm) |

| Rated Pressure Differential (Relative to Ambient) |

-125 to 0 Pa (-0.5 to 0 in H2O) |

| Temperature Range | 0 to 30°C (32 to 86°F) |

| Humidity | 5 to 90%, non-condensing |

| Approvals | CE Marking, Special Inspection CSA/UL |

ADS-A20 Diluter with Sono-Tek Disseminator Option

| Particle Size | 1 to 10 microns |

| Liquid Dissemination Volume | 2 x 60 mL (2 oz) syringes |

| Dissemination Rate | 240 to 2400 Microliters per minute |